We provide machining applications engineering and integration solutions for your most complex manufacturing challenges. At Productivity, we understand that capital equipment projects can be complex. That’s why even before you purchase a machine tool from Productivity, our sales team and Applications Engineering experts work together to fully comprehend your unique needs to present you with a customized engineering program to solve challenges and expand opportunities.

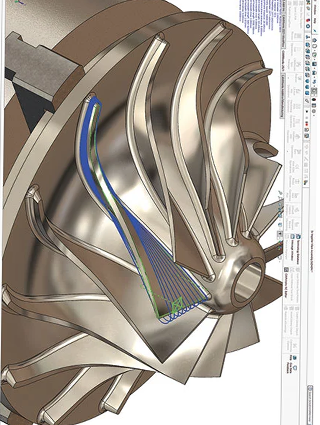

SARV provides reliable CNC programming to match client requirements. With details such as drawings of the part in readable format, machine specific details, blank material and size, available tools list, and sample program, we can provide CNC lathe, horizontal machining center, vertical machining center, VTLs, 4&5 axis machines, Turn-Mill / Mill-Turn 5 Axis detailed cycle-time sheet, tools list, and operation-wise machining details.

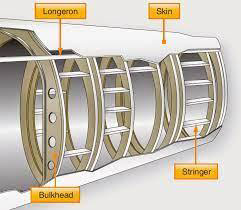

From machine tool and tooling selection, to machine tool integration, to process automation, to controller programming, to fixture design, to part work holding and multiple axis programming, to machine cell layouts, to production ready-processes, we analyze every aspect of your operation.

As a single-source supplier, we also have access to all products and services necessary to get the job done in-house. Our CNC Engineering Services include:

• TurnKey Solutions

• Engineering Process Assistance

• CAD-CAM Software Skill Development Training

What are the Benefits of Choosing SARV for CNC Services?

- Serving global clients for over 5 years, at SARV, we have the required expertise to provide customized services to all our global clients. However, the following are some of the major paybacks of choosing us for CNC services outsourcing –Showcased excellence in recording zero unsolved customer/supplier related complaints defects, this was mainly achieved through 8D measures

- Acknowledged and honored for increasing in-plant capability by 90% through improvements in the Cutting Tool and optimizing the programming.

- Played a vital role in reducing the variable production cost per kg by 20%, this was attained mainly through raw material improvement

- Multi time zone, multi-operating system, multi-axis programming support including Auto Probing.

- Cost-effective CNC support model

- Hassle-free scaling up or scaling down of CNC resource

- Best service in less time