Engineering Excellence

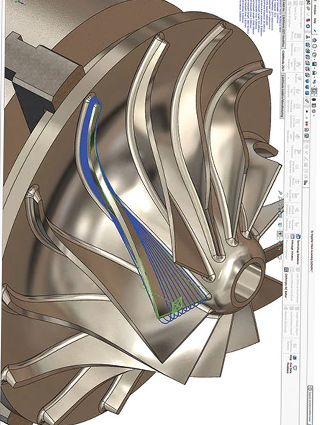

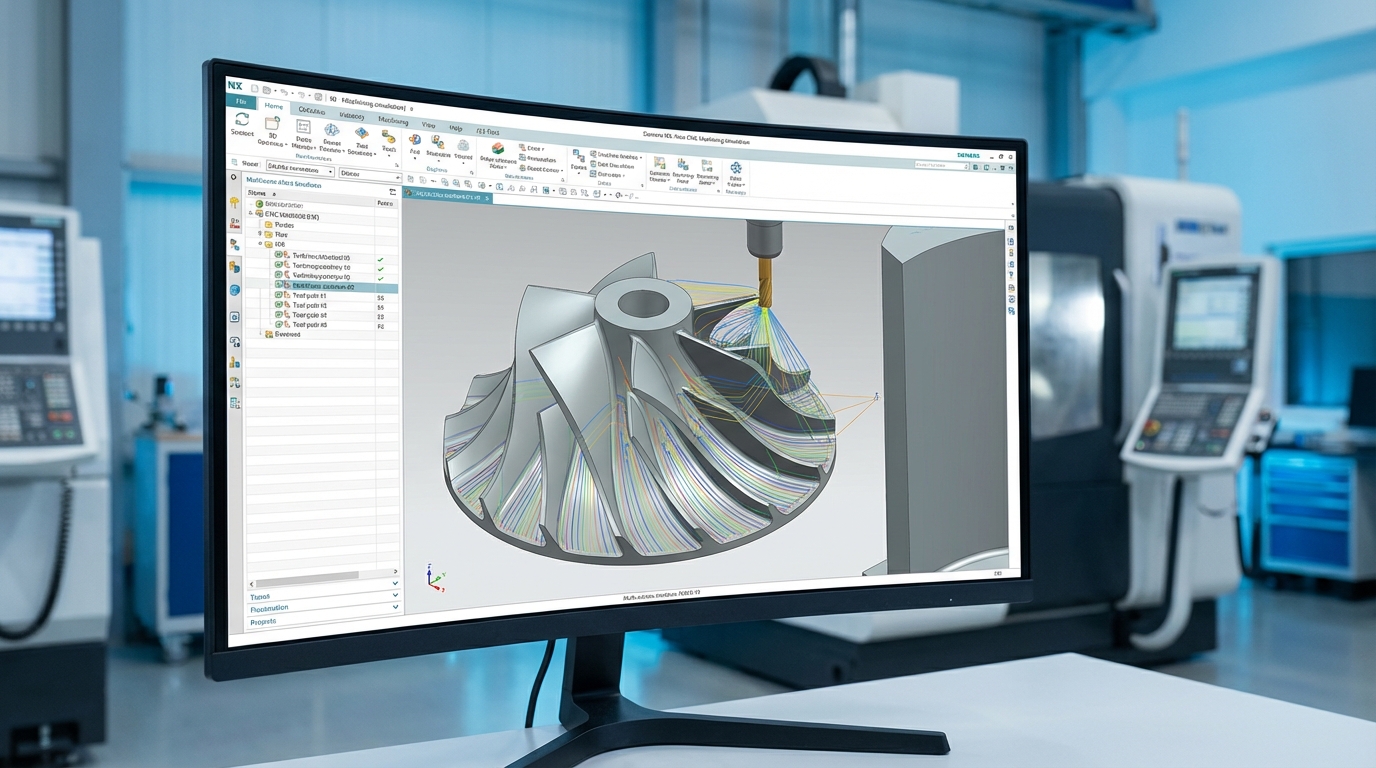

Machining Applications Engineering

We provide machining applications engineering and integration solutions for your most complex manufacturing challenges. Our experts work together to fully comprehend your unique needs to present you with a customized engineering program to solve challenges and expand opportunities.

Consult Our Experts